The performance of liquid silicone products has excellent transparency, strong tear resistance, resilience, anti-yellow, thermal stability, heat aging and weather resistance, while moderate viscosity, good fluidity, easy operation, high transparency of products.

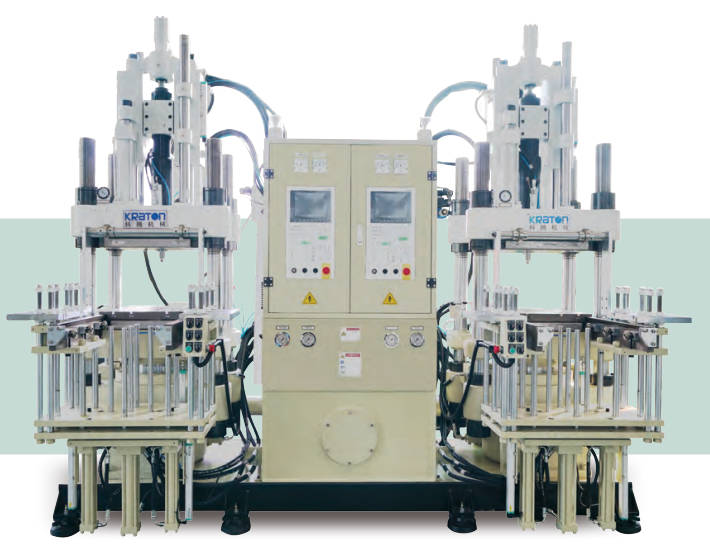

In recent years, the injection molding method of liquid silica gel has become a widely concerned and used molding method in the industry because of its advantages of automatic molding in a short time and plastic composite molding.

Liquid silicone injection molding method is to pump the addition of solidified liquid silicone rubber into injection molding, curing molding in the model method. It has the following advantages:

- Liquid silicone products are completed in a closed environment, compared to more environmental protection, no secondary pollution;

- The production efficiency is higher than the high temperature molding;

- The automation of equipment can save labor costs in feeding, metering and other work;

- Suitable for composite molding: silica gel material has good fluidity, low molding pressure, and wide curing temperature range, so in addition to embedding parts can also be composite molding.

Due to the excellent performance of silicone products (heat resistance, cold resistance, weather resistance, as well as electrical insulation and flame retardant, etc.).

The application range is very wide, such as: computers, mobile phones and other buttons, as well as bottles of pacifiers, baking molds, etc., so liquid silicone is also involved in many fields.

The molding process can not only save manpower, but also reduce material costs, from the point of view of environmental protection, this process is very popular and widely used.