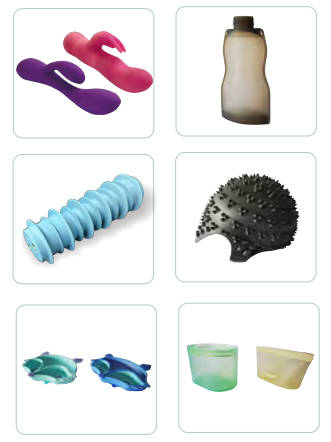

Can use LSR materials iwth compression molding molds.Very high cost-efficiency

Equipped with a heating board.The mold does not require its own heating function

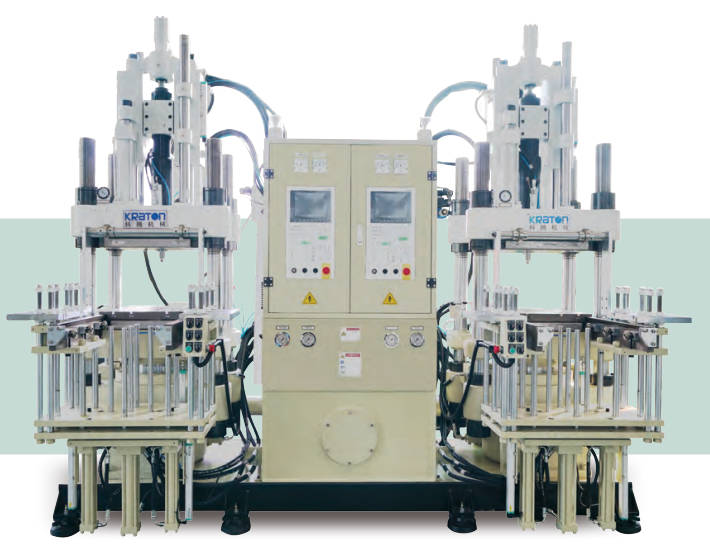

Unique machine design and features.

Optional:Double KEBA control panel with wide range of HMI panels with keywords, singleor multitouch operation

Best-in-class prduction efficiency, with integrated dual station molding, operated by independent control systems for double capaacity

Parameters

| SPECIFICATION | UNIT | KT-VK-200 | KT-VK-250 | ||||||

| Injection Unit | Screw Diameter | mm | 40 | 45 | 50 | 55 | 60 | 65 | |

| Injection Volume | g | 352 | 445 | 550 | 653 | 778 | 913 | ||

| Max Injection Pressure | kgf/cm^2 | 3010 | 2397 | 1927 | 1592 | 1338 | 1140 | ||

| Nozzle Out From Platens | mm | 50 | 50 | ||||||

| Clamping Unit | Clamping Force | Kn(tf) | 200 | 250 | |||||

| Clamping stoke | mm | 300 | 400 | ||||||

| Min Mold Thickness | mm | 50 | 50 | ||||||

| Max Opening | mm | 350~600 | 450~800 | ||||||

| (L*W) Max Mold Size | mm | 600*600 | 700*700 | ||||||

| (L*W) Mold Size | mm | 600*600 | 700*700 | ||||||

| Lift Plate Angle | 50 | 50 | |||||||

| Others | System Pressure | Mpa | 18.6 | 18.6 | |||||

| Motor Power | KW | 19.3 | 19.3 | ||||||

| Machine Dimensions | L | mm | 2320 | 2620 | |||||

| W | mm | 2210 | 2700 | ||||||

| H | mm | 2970(3730) | 3420(4410) | ||||||

| Machine Weight | Ton | 5.7 | 8 | ||||||