Introduction:

Rubber compression molding machines play a crucial role in the rubber industry, enabling efficient and precise production of rubber parts for a wide range of applications. However, with numerous options available in the market, choosing the right machine can be a daunting task. To help you make an informed decision, we have compiled a comprehensive guide outlining key factors to consider when selecting a rubber compression molding machine.

Determine your production requirements:

One of the first steps in choosing a rubber press machine is to determine your specific production needs. Consider factors such as the type and volume of rubber parts you plan to produce, the required production speed, and the desired level of automation. This will help you narrow down the options and select a machine that aligns with your production requirements.

Quality and Durability:

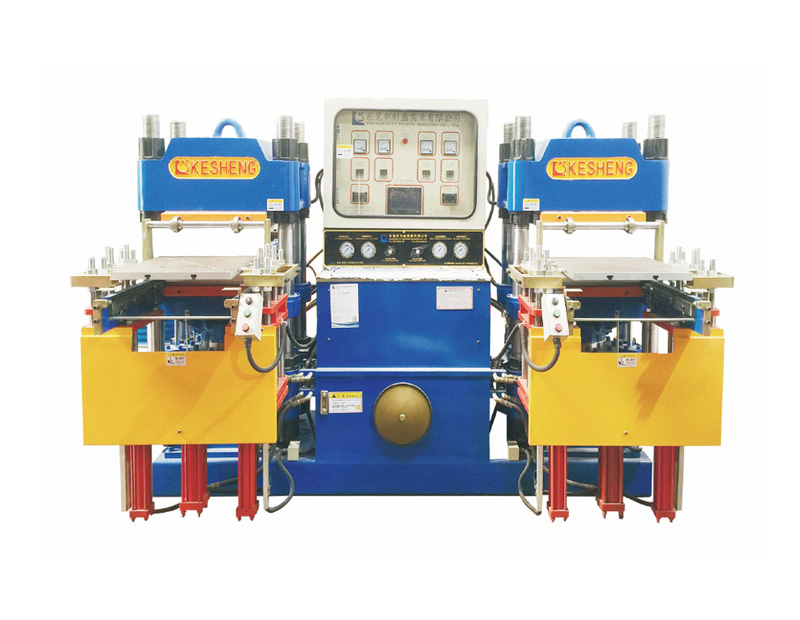

Investing in a high-quality and durable rubber compression molding machine is essential for long-term productivity and reduced maintenance costs. Look for machines manufactured by reputable companies with a proven track record in the industry. Check for features like robust construction, reliable hydraulic systems, and precision in the molding process.

Mold Compatibility:

Ensure that the machine you choose is compatible with the molds you will be using. Consider the mold dimensions, mold opening stroke, and the number of cavities that the machine can handle. Compatibility between the machine and mold is crucial for achieving accurate and consistent finished products.

Control System and Automation:

The control system of the rubber mould machine plays a vital role in ensuring efficient operation and producing high-quality rubber parts. Look for machines with user-friendly control panels that offer customization options, process monitoring, and data logging. Consider the level of automation you require, such as automatic mold changing, robot handling, or conveyor systems, to improve productivity and reduce manual labor.

Energy Efficiency:

With environmental concerns and rising energy costs, choosing an energy-efficient rubber compression molding machine is both economically and environmentally advantageous. Look for machines that incorporate energy-saving features, such as variable frequency drive systems, energy recovery systems, or advanced heating methods, which can significantly reduce power consumption.

After-Sales Support:

Selecting a manufacturer that provides reliable after-sales support and technical assistance is vital. Check for warranties, availability of spare parts, and the manufacturer’s reputation for customer service. A manufacturer with a responsive and knowledgeable support team can help troubleshoot issues and keep your machine running optimally.

Conclusion:

Choosing the right rubber compression molding machine is a critical decision that can impact the efficiency and profitability of your rubber manufacturing operations. By considering factors such as production requirements, quality, mold compatibility, control system, energy efficiency, and after-sales support, you can make an informed decision that aligns with your specific needs. Conduct thorough research, compare multiple options, and consult with industry experts to ensure you acquire a machine that meets your expectations and delivers superior performance.