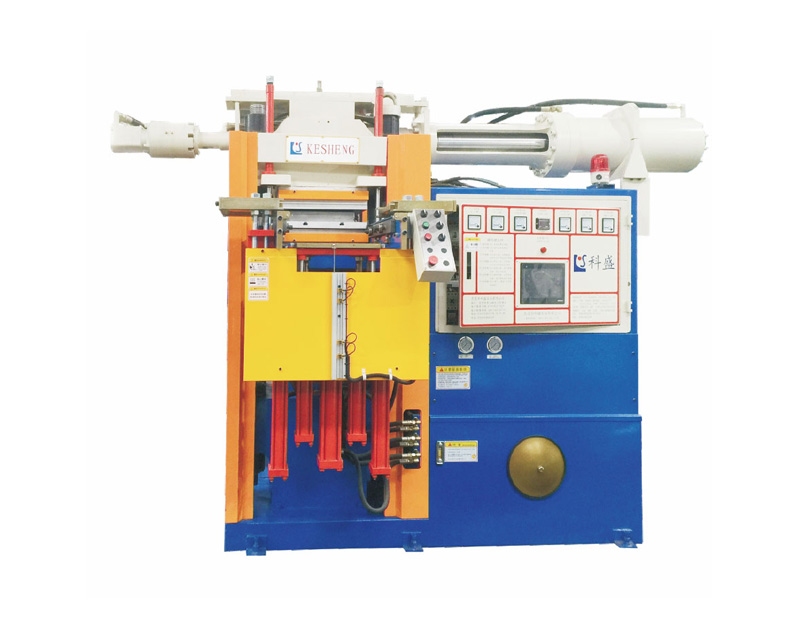

Rubber injection molding machine is a technology to produce rubber molded products, mainly used in the production of rubber molded products such as insulation, shockproof cushions, gaskets, shoes, boots etc. It has been widely used in the country, the main characteristics of the rubber press machine is to use a simplified method, high temperature vulcanized rubber can shorten the production cycle, the size is accurate, the uniform mechanical properties, high quality, especially thick vulcanized products are more suitable for operating procedures than simple ones, reducing labor intensity, and high degree of mechanization and automation. The basic rubber production process consists of six basic processes: plasticizing, mixing, rolling, extrusion, molding and vulcanization. The rubber processing process is mainly to solve the contradiction between elasticity and plasticity. Through different processing methods, elastomer rubber is made into plastic by mixing the mixture into different semi-finished products, and then vulcanized, with high flexibility, good mechanical and mechanical properties of the product. rubber products.

Rubber molding machine is one of the information technology problems in the production of rubber molded products, mainly used in the company that produces rubber molded products such as insulating parts, shockproof cushions. , gasket, shoe sole, industrial and mining boots etc.

It has been widely researched and used at home and abroad, the main working characteristics of the rubber press machine is to simplify the processing technology, can achieve high temperature vulcanized rubber product, shrink Short production time and precise social operation, product size, uniform mechanical properties, high quality. The casting vulcanization of thicker-walled products is especially suitable for selection, the project management operation method is simple, the labor relationship strength is continuously decreasing, the degree of proficiency is high, and the degree of automation is high. high, the basic structure of the rubber injection machine includes: elastic injection part: the core component of the plastic injection device is the rubber injection machine, the resource consumption is concentrated and the gas retention, the density is uniform, easy to replace rubber, clamping device: the main part of clamping device is rubber injection molding machine, vulcanizing tank.

Digital teaching quality aspect plays an important role, high production efficiency, more convenient operation, control environment system and control network system is the brain. Accuracy, stability and the decisive role of the rubber press is mechanical energy consumption, safe and effective protection, the rubber press is a necessary component to ensure knowledge production safe. Safety protection system designers mainly need to consider the convenience, efficiency and usage habits of workers, make the most of the equipment’s safety protection device, and humanize the operation process. production and lack of clear instructions, the foundation of production and development has been solidified.