Below we have sorted out a few differences between liquid silicone and solid silicone to help you better understand.

Liquid silicone application situation:

- Food grade ingredients should be in contact with food and human or skin friendly needs such as maternal and child products and kitchen utensils.

- Products requiring high transparency and visibility such as diving supplies, frogglasses, oxygen masks.

- Medical uses involving highly biocompatible raw materials such as medical appliances, diagnostic AIDS, and human invasive silicone implants.

- High technical threshold and clean room production requirements such as optical products.

Solid silicone application situation:

- Industrial miscellaneous parts, auto parts and other non-complex structure of the inner components, O-ring, silicone dust cover, silicone dust plug, etc.

- Products have multi-color, a large number of post-processing products such as remote controller buttons, instrument operation panel buttons.

- Develop low-cost products with low budgets and simple manufacturing processes.

- Small quantities of customized products with small demand

| Liquid silicone | Solid silicone | |

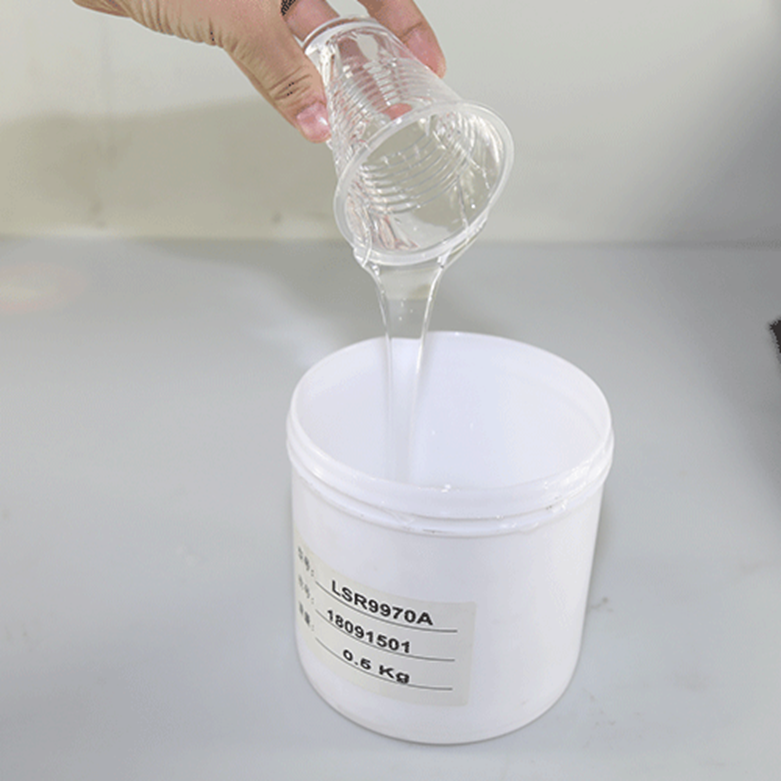

| Raw material processing | Deployed before the line, sealed drums | Before going online, it is still necessary to adjust and add the auxiliary agent by itself, and the open box is packed |

| Product tolerance | Precision, almost no frills | Large, obvious raw edge |

| Product appearance | High transparent, no obvious mold line | Semi-transparent fog, there is an obvious closing line |

| Process technology | After the mold is closed, the machine works automatically | Advanced material after closing mold, manual operation |

| Manufacturing technology | The technology door is high | Technical door is low |

| Environmental pollution | Low ((production process does not produce waste) | Higher (production process produces more waste) |

| Range of application | High precision requirements and large quantities of products | Products that are non-appearance parts with large tolerances and budget considerations |

Due to the excellent performance of silicone products (heat resistance, cold resistance, weather resistance, as well as electrical insulation and flame retardant, etc.).

The application range is very wide, such as: computers, mobile phones and other buttons, as well as bottles of pacifiers, baking molds, etc., so liquid silicone is also involved in many fields.

The molding process can not only save manpower, but also reduce material costs, from the point of view of environmental protection, this process is very popular and widely used.