The frame of a rubber press is the essential infrastructure that provides the necessary support for other components of the machine to function effectively.

Just like the frame of a house supports the roof, protects the interior, and provides the necessary structure to fulfill its function, the same can be said for the importance of the frame in a rubber press, also known as a hydraulic press.

There are many types of press frames available on the market, with each type depending on the kind of work or the production environment in which you need the press to operate. Head Tech would like to explain why knowing the “type” of hydraulic press frame is so important.

As a reputable and high-quality supplier of rubber presses, or hydraulic presses, we can confidently say that we have a deep understanding of these machines. Head Tech can design and manufacture custom rubber presses tailored for even the most complex applications based on specific customer requirements.

Even when customers are unsure of exactly what they need, Head Tech will always help them understand which press is best suited for their business and the real importance of the type of hydraulic press frame.

Types of Press Frames:

Monolithic Frame:

This is a large press made from a single, rigid block that resists twisting. It is a cost-effective option when you need a rubber press with a sturdy frame and a simple design.

4-Column Frame:

This type of frame allows for material input and product removal from all four sides of the mold area, primarily designed to facilitate automation. It enables easy mold changes and convenient product loading and unloading, increasing flexibility in every operation.

Rubber presses with a 4-column frame are an ideal choice for applications requiring quick changeovers and high automation.

Pre-stressed Housing Frame:

This option is suitable for applications requiring high loads, withstanding force using several individual structural components. When combined with load-bearing tie rods in the frame, it allows the press to handle loads exceeding 30,000 tons.

Multi-frame Press:

This is a high-pressure rubber press (hydraulic press) consisting of multiple frame structures mounted on two base beams to ensure precise positioning. The multi-frame press is named for its multiple heavy-duty welded frames.

Its modular structural components allow for easier handling, and the multiple frame structures make transportation more manageable. It offers the ability to handle off-center loads and has a compact design for a high-pressure press with a small press bed size.

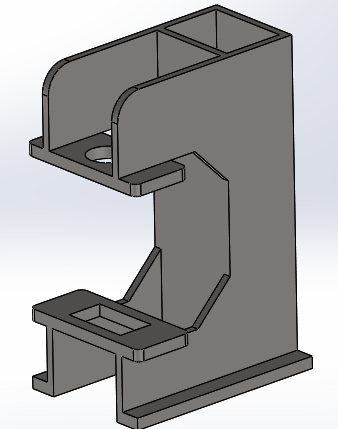

Gap Frame or C-Press:

The open-frame design allows for material input and product removal from three sides and is an economical solution for businesses requiring low-cost machinery. The open-frame press is often referred to as a C-frame press, named for its unique “C” shape around the base plate. This is an economical option for applications with a small press bed and low load capacity.

Side Slab Frame Press:

This type of frame allows for a larger press bed, with frame components joined together using rivets and load-bearing bolts. Side slab frames offer better eccentric load handling with low deflection. Extrusion and compression molding are typically performed on side slab presses.

At Head Tech, we understand that the quality of a rubber press frame can have a significant impact on the overall efficiency and safety of machinery, products, or tools. Meeting customers’ goals and price expectations is an important part of our manufacturing process, and Head Tech is always ready to assist.

Contact us online or call us at 0708.141.698.