If the advantages of liquid silicone rubber are so many, then why so far the manufacturing and production of industrial.

Technological industries are still based on solid silica gel, mainly because the two processes have their suitable product applications and market positioning.

Below we have sorted out a few differences between liquid silicone and solid silicone to help you better understand.

- Raw material processing variance

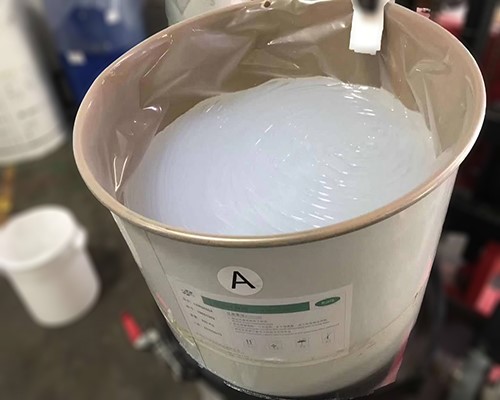

Liquid silicone: mostly two-component (AB) liquid silicone rubber, also known as AB rubber. Raw material processing uses platinum as a catalyst for vulcanization. The general ratio of AB agent is 1:1 or 10:1, depending on the formula of the raw material manufacturer. The packaging method is mostly 1:1 liquid barrel, and the capacity is 10KG/20KG/25KG to 200KG. After delivery, the raw material can be made directly without adding vulcanizing agent or any processing.

Solid silicone: a single component silicone rubber, mostly vulcanized by organic peroxides. Raw materials are packed in solidified rubber block boxes, and then the processing of raw materials before forming is completed by the processing manufacturer of silica gel products through mixing and adding auxiliary materials such as curing agent according to the demand.

- Forming method difference

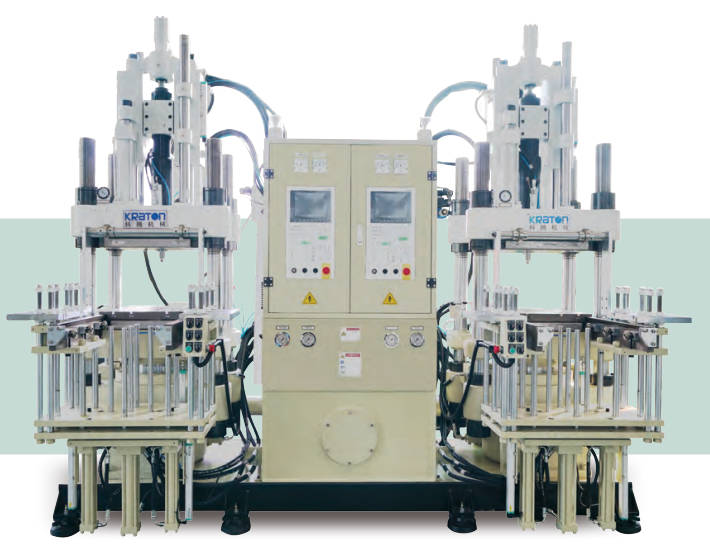

Liquid silicone: Like the mode of plastic Injection molding, the liquid silicone AB raw material is directly passed through the liquid injection (injection) forming Machine (English name: Liquid Injection Machine abbreviation: After the static mixer of LIM is automatically blended, the injection tube is injected into the closed mold cavity and the product is heated to complete the molding.

Solid silicone: the mixed raw material (silicone rubber block) is cut into the appropriate size of the finished product and the mold cavity and placed on the open mold, and then the mold is closed and molded by the oil press forming machine according to the set pressure temperature.

- Process differences

Liquid silicone: accurately control the dosage of the feed, and inject the raw material into the closed mold. The size is more precise, the tolerance is small, the raw edge is fine, the appearance is exquisite, and the degree of automation is high. Low molding temperatures up to 130°C are acceptable.

Solid silica gel: manual cutting, placing raw materials before closed mold molding. The size is difficult to control, the raw edge is large, and the closing line needs to be self-disassembled. High temperature molding above 180°C is required.

- Surface appearance difference

Liquid silicone: raw material transparency is high, the finished product has no obvious mold line, the raw edge is small (not easily detected by the naked eye), and the product has a glue mouth.

Solid silicone: the raw material transparency is low, generally milky translucent color, the raw edge of the finished product is more obvious, and the product has no glue mouth.

- Security variance

Liquid silicone: Since liquid silicone from raw material processing to sealed packaging is completed in clean space or even clean room, the production stage is also sealed feeding molding. It is fed into the mold cavity in the closed pipeline, and the process is completely out of contact with the outside world, which can be said to control the cleanliness of the product to the highest degree and eliminate environmental pollution. High quality pure no smell, can be said to be from the inside out of the peace of mind guarantee.

Solid silicone: The same silicone raw materials, in a broad sense, solid silicone itself is also safe and non-toxic, the reason why the liquid silicone is slightly inferior is mainly reflected in the cleaning problems caused by the limitations of the two processing processes and the difference in environmental requirements, coupled with the low transparency of solid silicone, which is easy to cause poor perception or impurities are not easy to be found, in addition, Solid silica gel raw material processing need to add vulcanizing agent and other additives, often have odor and other phenomena.

First off I would like tto say terrific blog! I had a quick question in which I’d like too askk

if you do not mind. I was curious to know how you cenmter yourself and clear your head

before writing. I have had a tough time clearing my mind in getting my thoughts outt there.

I truly do enjoy writing bbut it just seems like the first 10 to 15minutes are generally lost just

trying to figure out how to begin. Any ideas

or hints? Thank you!