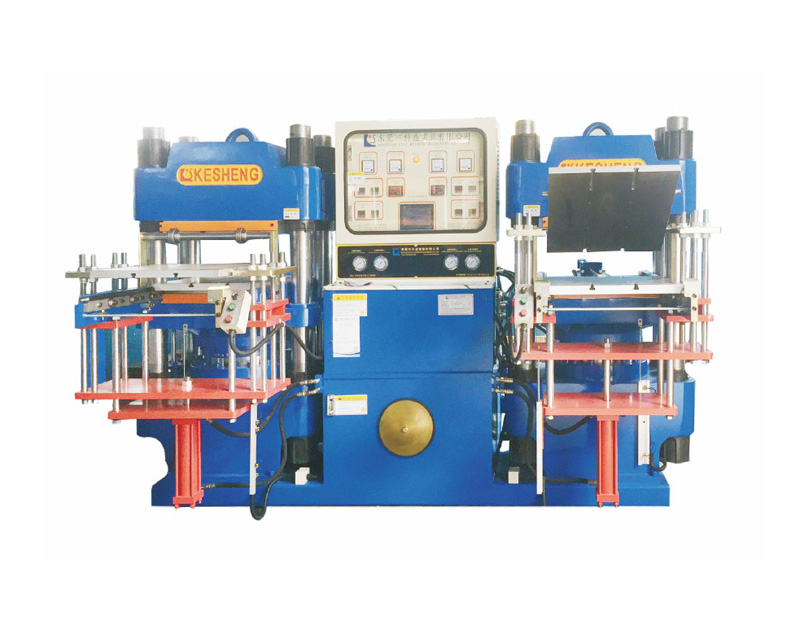

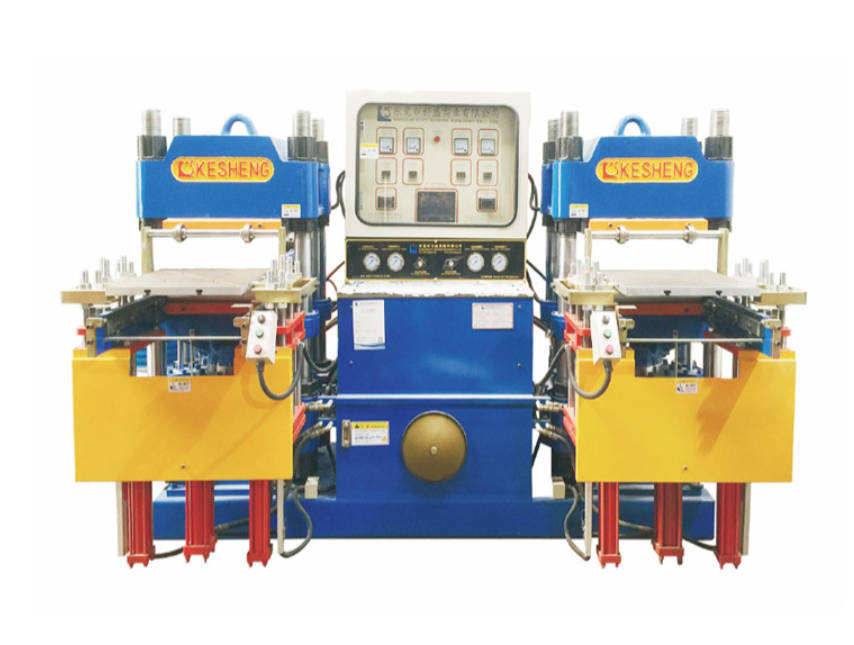

- Rubber Compression Molding Machine use automatic or manual control, with reliable performance and high automation. Can automatically identify wrong commands to avoid problems caused by wrong operations.

- The pre-programmed process can be locked , so that the operator cannot change it to ensure the quality of the pressed product.

- It has functions such as setting mold opening time, automatic deflation, automatic pressure addition etc.

- There are 3 operating modes to choose from: manual, semi-automatic and automatic.

- The electric heating press uses digital display temperature control (monitor) to control and display the temperature of the heating plate

The vulcanizer machine is suitable for major products such as O-rings, remote controls, pressure cookers, cooker gaskets, home appliance accessories, food accessories, hygiene and medical equipment. Manufacture of pacifiers, medical supplies, healthcare supplies, handicrafts, toy gaskets, conductive rubber, automotive rubber parts, industrial rubber parts, medical silicone products economy, sports equipment, various instruments, multi-layer molded products, rubber and silicon parts, and other complex manufacturing and processing.