Three types of silicone products: silicone mold, extruded silicone and liquid silicone.

- Silicone mold:

Silicone products are typically produced by placing raw solid silicone mixed with a vulcanizing agent into a mold at high temperatures. The silicone is then pressurized using a vulcanizing machine and cured at high heat until it solidifies.

The hardness of the cured silicone generally ranges from 30°C to 70°C. Pigments can be added to the raw material to achieve the desired color, matched according to the Pantone color chart. The shape of the mold determines the final form of the silicone product.

Silicone casting is one of the most widely used processes in the silicone industry, commonly applied to produce industrial accessories, buttons, silicone gifts, bracelets, watches, key covers, phone cases, kitchenware, mats, ice trays, and cake molds.

- Extruded silicone:

Extruded silicone products are typically created by extruding silicone through an extruder. These products usually take the form of long rods or tubes, which can be cut to any desired length.

However, the shapes of extruded silicone are somewhat limited. Despite this, extruded silicone is widely used in medical equipment and machinery.

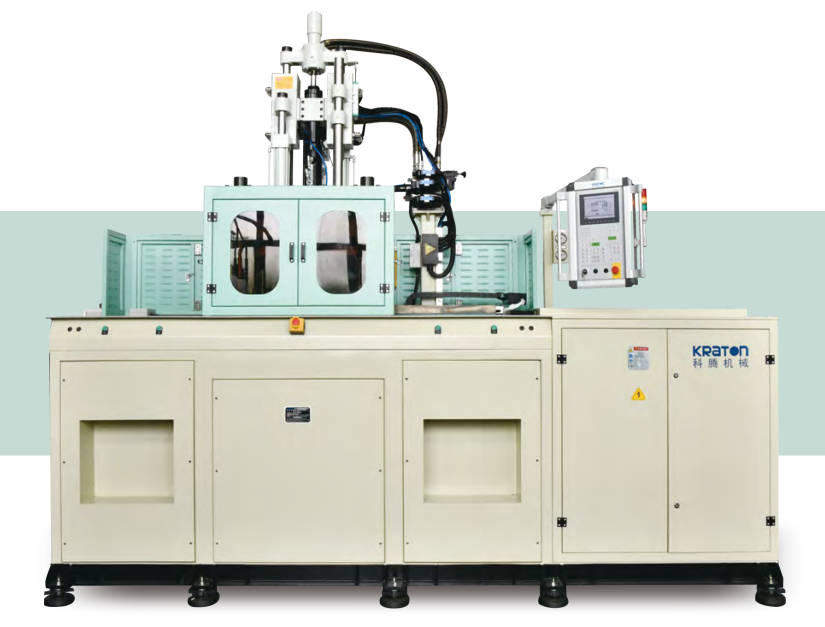

- Liquid silicone:

Liquid silicone products are manufactured through silicone injection molding. These products are soft, with hardness levels ranging from 10° to 40°. Due to their softness, they are commonly used in applications such as human body part simulations and medical silicone chest pads, etc.